How Robotic Machining Works to Improve Efficiency and Productivity?

In the ever-evolving landscape of manufacturing and production, staying competitive means finding innovative ways to enhance efficiency and productivity. Robotic machining has emerged as a transformative technology, revolutionizing how industries approach precision manufacturing and complex tasks. In this article, we will delve into the world of robotic machining, exploring its benefits, applications, and how it's driving the future of manufacturing.

The

Power of Robotic Machining

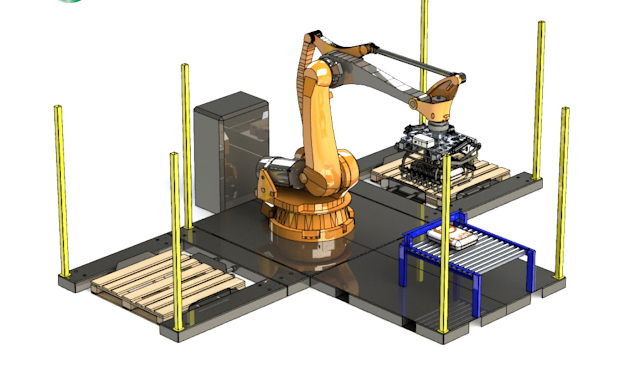

Robotic machining, also known as CNC

(Computer Numerical Control) machining with robots, involves the use of

automated systems equipped with robotic arms to perform machining operations.

These operations include milling, drilling, cutting, grinding, and more. Unlike

traditional CNC machines, which are typically stationary, robotic machining

offers unparalleled flexibility and adaptability.

Key

Benefits of Robotic Machining:

· Precision and Consistency: Robots excel

at maintaining precision and consistency in machining tasks, reducing errors

and ensuring high-quality output.

· Versatility: Robotic machining can be

programmed to handle a wide range of materials, from metals to composites, and

adapt to various part sizes and complexities.

· Efficiency: Robots work tirelessly

without breaks or fatigue, resulting in higher productivity levels and reduced

production time.

· Safety: By automating tasks that can be

hazardous to humans, such as working with heavy machinery or in extreme

temperatures, robotic machining enhances workplace safety.

· Cost-Effective: While the initial

investment in robotic machining can be significant, the long-term cost savings

through reduced labor and increased efficiency often justify the expense.

Applications

of Robotic Machining:

· Aerospace Industry: Robotic machining is

used extensively in the aerospace sector to produce complex and precision

components for aircraft and spacecraft. The ability to work with lightweight materials

like aluminum and titanium makes robots invaluable in this industry.

· Automotive Manufacturing: Robotic

machining is employed for tasks such as milling engine components, trimming

parts, and creating molds for automotive bodies. The automotive industry

benefits from the speed and accuracy of robotic machining.

· Medical Device Manufacturing: Precision

is paramount in medical device manufacturing. Robots are used to create

intricate components for devices like prosthetics, orthopedic implants, and

surgical instruments.

Mold and Die Making: The production of

molds and dies for injection molding and die-casting can be time-consuming and

labor-intensive. Robotic machining streamlines this process, allowing for

faster turnaround times.

Art and Sculpture: Even in the world of

art and sculpture, robotic machining has found a place. Artists can use robots

to carve intricate designs into various materials, pushing the boundaries of

creativity.

Enhancing

Productivity and Efficiency:

Robotic machining offers several ways to

enhance productivity and efficiency in manufacturing:

24/7 Production: Robots don't need rest,

which means continuous production without downtime, leading to faster project

completion.

Reduced Scrap: Precision and consistency

minimize errors, reducing the number of flawed parts and materials wasted

during production.

· Programming Flexibility: Robots can be

reprogrammed swiftly to adapt to new tasks or product variations, reducing the

need for extensive retooling.

· Data-Driven Optimization: Robotic systems

can be equipped with sensors and monitoring tools that collect real-time data,

allowing for process optimization and predictive maintenance.

· Human-Robot Collaboration: While some

tasks are entirely automated, collaborative robots (cobots) can work alongside

human operators, leveraging the strengths of both to maximize productivity.

Conclusion:

Comments

Post a Comment